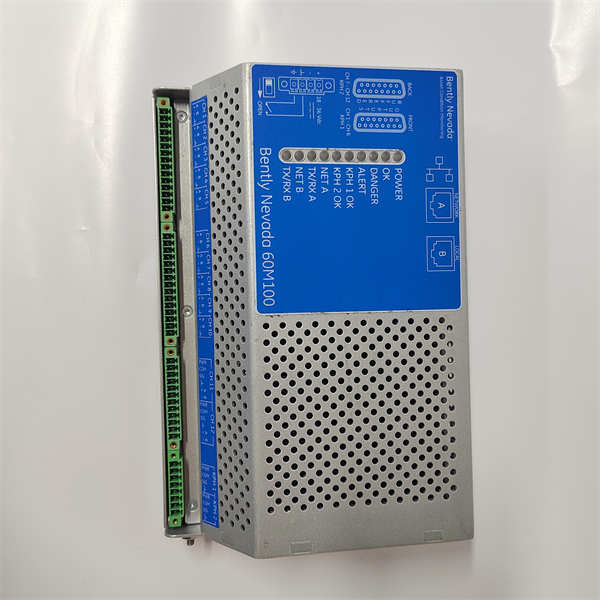

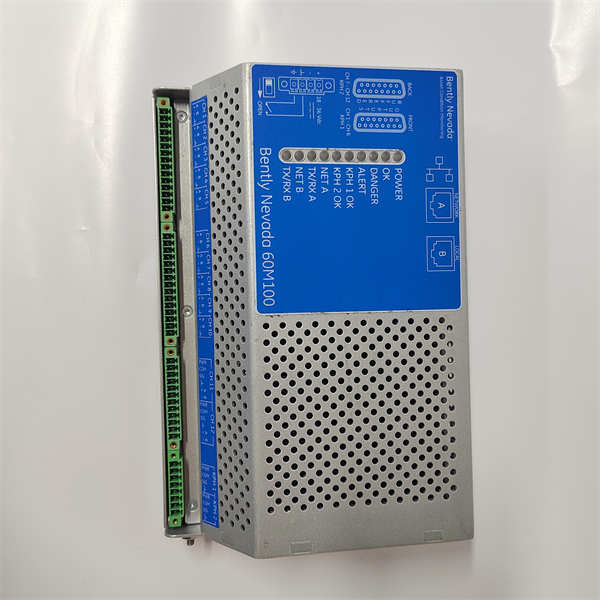

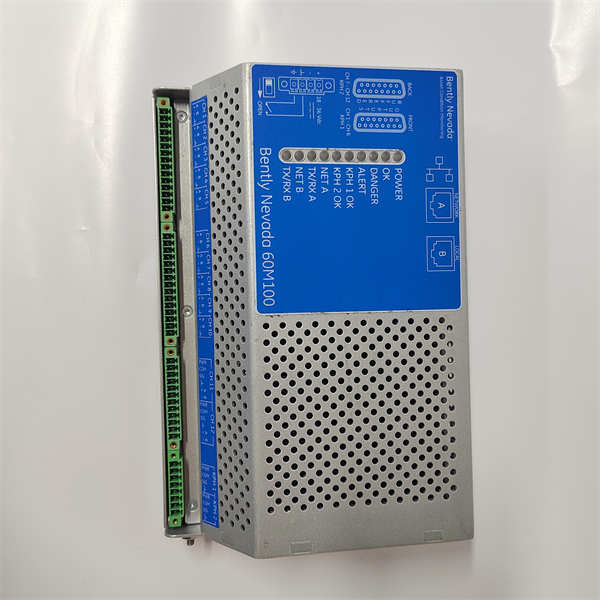

The BENTLY NEVADA 60M100-00 is a high-reliability, single-slot power supply module designed specifically for the 3500/46M rack within the renowned Bently Nevada machinery condition monitoring system. This module serves as the primary or redundant power source, delivering clean and stable power to all monitoring modules in the rack, which is critical for the continuous protection of valuable industrial assets like turbines and compressors.

In a gas turbine power plant, the Bently Nevada 3500 system is the first line of defense against catastrophic mechanical failure. The BENTLY NEVADA 60M100-00 power supply module is installed in the 3500/46M rack, powering vibration, position, and temperature monitors. Its robust design ensures that even during plant-wide voltage sags or transients, the monitoring system remains fully operational, providing uninterrupted data to trigger alarms and initiate equipment shutdowns if dangerous conditions are detected, thereby safeguarding millions of dollars in equipment.

Main Parameters | Value/Description |

Product Model | BENTLY NEVADA 60M100-00 |

Manufacturer | Bently Nevada (A Baker Hughes Business) |

Product Category | Power Supply Module |

Compatible Rack | 3500/46M Rack |

Input Voltage Range | 85-265 VAC, 47-63 Hz; or 90-150 VDC (Wide range for global use) |

Output Power | 100 Watts (Sufficient for a fully populated rack) |

Output Voltage | +5 VDC, ±15 VDC (Powers all 3500 series monitoring modules) |

Redundancy | Supports N+1 redundant configuration (For maximum system availability) |

Status Monitoring | LED indicators for power and fault conditions |

Safety Certifications | cULus, CE, ATEX (for hazardous areas) |

· •Innovation Point 1: Robust Power Conditioning for Critical Systems. The 60M100-00 incorporates advanced filtering and regulation circuits that provide exceptional immunity to input power noise, spikes, and sags. This ensures that the sensitive monitoring modules receive clean, stable power, which is fundamental for obtaining accurate and reliable measurement data from the transducers.

· •Innovation Point 2: Seamless N+1 Redundancy for Maximum Uptime. The module is designed for redundancy. When two 60M100-00 modules are installed in a rack, they share the load. If one fails, the other automatically takes over the full load without any interruption to the monitoring system, a critical feature for 24/7 operations where unplanned downtime is not an option.

· •Innovation Point 3: Comprehensive Diagnostics and Hot-Swap Capability. The module features clear LED status indicators for immediate visual health checks. More importantly, it is hot-swappable, meaning a faulty unit can be safely replaced while the rack remains powered on and operational, ensuring continuous asset protection.

In a large petrochemical refinery, a critical centrifugal compressor was protected by a Bently Nevada 3500 system. During a severe lightning storm, a power surge damaged one of the two redundant BENTLY NEVADA 60M100-00 power supplies. The system seamlessly continued operation on the remaining power supply without missing a single data sample. The hot-swap capability allowed maintenance personnel to replace the failed module during a planned operational window, avoiding a costly emergency shutdown and potential production losses exceeding $1 million per day.

· •BENTLY NEVADA 3500/42M: A proximity transducer interface module that is powered by the 60M100-00, providing vibration and position data.

· •BENTLY NEVADA 3500/25: A keyphasor module, critical for phase reference, which relies on the stable power from the 60M100-00.

· •BENTLY NEVADA 3500/22M: A transient data interface module, whose operation depends on the clean power supplied by the 60M100-00.

· •BENTLY NEVADA 3500/15: A temperature monitor module, powered by the 60M100-00 to accurately monitor bearing temperatures.

· •BENTLY NEVADA 3500/92: A communication gateway that relays data from the rack to the plant DCS, all powered by the reliable 60M100-00.

Installation of the BENTLY NEVADA 60M100-00 is a straightforward process of sliding it into a power supply slot in the 3500/46M rack. The hot-swap design is a key feature, allowing for safe maintenance without system shutdown. Wiring is connected to the rack's terminal block, and status is monitored via the LED on the front panel.Routine maintenance involves periodic visual inspection of the status LED and checking the system diagnostics via the 3500 software. The module's robust design ensures long-term reliability. We provide comprehensive lifecycle support, from initial system configuration to 24/7 technical support and a guaranteed supply of genuine, factory-tested BENTLY NEVADA 60M100-00 power supply modules to minimize your system's downtime risk.

扫一扫咨询微信客服

扫一扫咨询微信客服