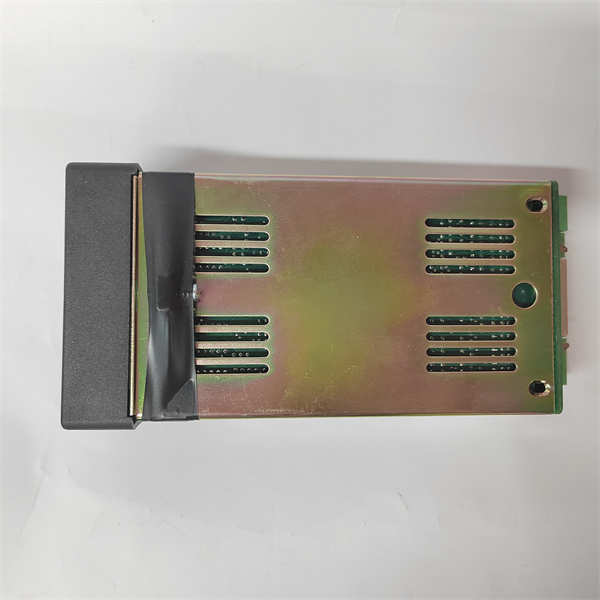

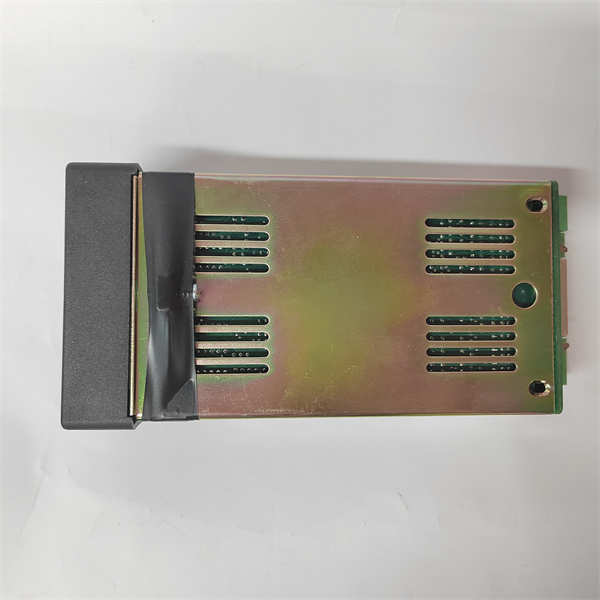

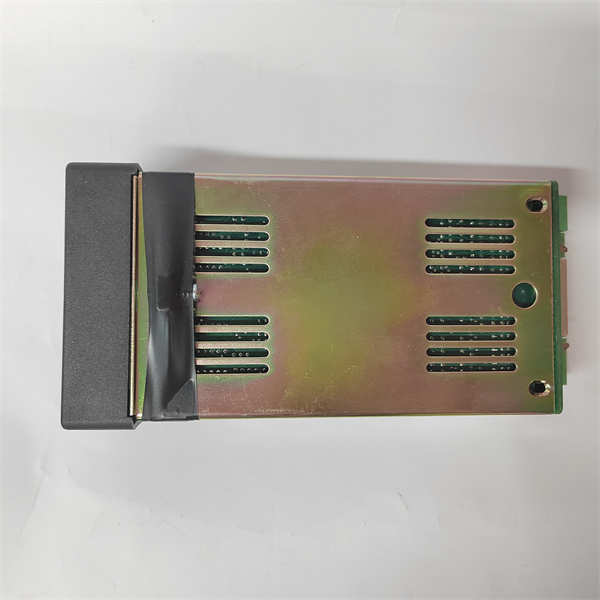

The WATLOW ANAFAZE CAS200 is a high-performance, multi-loop process controller manufactured by Watlow, a global leader in thermal system solutions. This robust controller is engineered to deliver precise temperature and process control for demanding industrial applications, ranging from heat treatment furnaces to semiconductor manufacturing equipment.

In a semiconductor diffusion furnace, precise temperature control across multiple heating zones is critical to ensuring the quality and integrity of silicon wafers. The WATLOW CAS200 is deployed as the central control unit, managing each zone independently. Its high-resolution control algorithms

maintain temperature stability within a fraction of a degree, directly addressing the pain points of thermal runaway and process deviation, which are vital for achieving high production yields and consistent product quality.

Main Parameters | Value/Description |

Product Model | WATLOW CAS200 |

Manufacturer | Watlow (Anafaze) |

Product Category | Multi-Loop Process Controller |

Control Loops | Configurable for multiple independent loops (e.g., 2, 4, or 8) |

Input Types | Thermocouple (J, K, T, etc.), RTD, Voltage (0-10V), Current (4-20mA) |

Output Types | Relay, SSR Drive, Analog (4-20mA), Digital Communication |

Control Algorithm | Advanced PID with Auto-Tune and Fuzzy Logic |

Communication Protocols | Ethernet/IP, Modbus TCP/IP, DeviceNet, PROFIBUS-DP |

Power Supply | 24 VDC or 100-240 VAC (Wide range for global use) |

Display | Optional high-resolution graphical or LED display |

Operating Temperature | 0°C to 70°C (Industrial grade) |

· •Innovation Point 1: Multi-Loop Architecture in a Compact Design. The CAS200 integrates control for multiple process loops into a single, compact unit. This reduces the need for multiple single-loop controllers, simplifying cabinet layout, wiring, and overall system integration while lowering the total cost of ownership.

· •Innovation Point 2: Advanced Adaptive Control Algorithms. Beyond standard PID, the controller features sophisticated algorithms like fuzzy logic that can anticipate process changes and adjust the output preemptively. This results in faster response times, reduced overshoot, and superior stability compared to conventional controllers, especially in complex, non-linear processes.

· •Innovation Point 3: Seamless Enterprise Connectivity. With built-in support for major industrial protocols like Ethernet/IP and Modbus TCP/IP, the CAS200 functions as a smart node on the factory network. It allows for real-time data monitoring, remote configuration, and recipe downloading from a central DCS or SCADA system, enabling Industry 4.0 connectivity.

A leading aerospace component manufacturer was experiencing inconsistencies in the heat-treating process of turbine blades, leading to a high scrap rate. The existing single-loop controllers could not coordinate the complex ramp-soak profiles across multiple furnace zones effectively. After retrofitting the system with a WATLOW CAS200, the plant achieved unprecedented thermal uniformity. The controller's precise multi-zone coordination and adaptive tuning reduced scrap by over 30% and improved energy efficiency by 15%, delivering a return on investment in less than one year.

· •WATLOW F4T Controller: A versatile touch-screen controller that can be used alongside the CAS200 for applications requiring a sophisticated local HMI for operators.

· •WATLOW POWER-FLASH Cartridge Heaters: High-performance heating elements that are perfectly matched to be controlled by the precise output of the CAS200.

· •WATLOW SENSORLYNG Sensors: High-accuracy RTDs and thermocouples that provide the critical temperature feedback required for the CAS200 to perform its control algorithms effectively.

· •WATLOW COM-X Communications Gateway: A device that can facilitate protocol conversion, helping to integrate the CAS200 into legacy control systems if needed.

· •WATLOW EZ-ZONE PM Integrated Systems: A complete modular heating system solution where the CAS200 can serve as the embedded control core.

Installation of the WATLOW CAS200 is designed for efficiency, typically involving DIN rail mounting. The terminal blocks are clearly labeled for straightforward wiring of inputs, outputs, and power. Configuration is achieved via intuitive Windows-based software, which guides the user through loop setup, tuning, and communication parameters.Routine maintenance is minimal, primarily consisting of verifying the calibration of connected sensors periodically. The controller's robust design ensures high mean time between failures (MTBF). We provide comprehensive lifecycle support, from initial application review and controller configuration to on-site commissioning assistance and 24/7 technical support. We guarantee access to genuine WATLOW CAS200 controllers and related components.

扫一扫咨询微信客服

扫一扫咨询微信客服