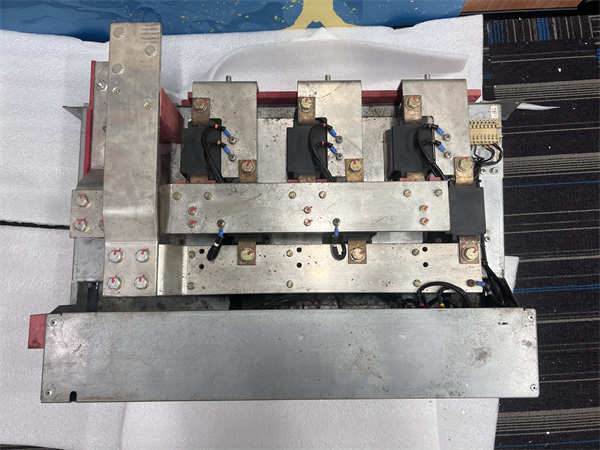

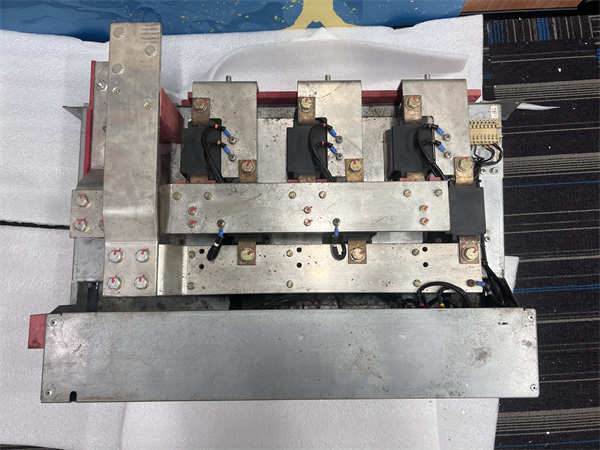

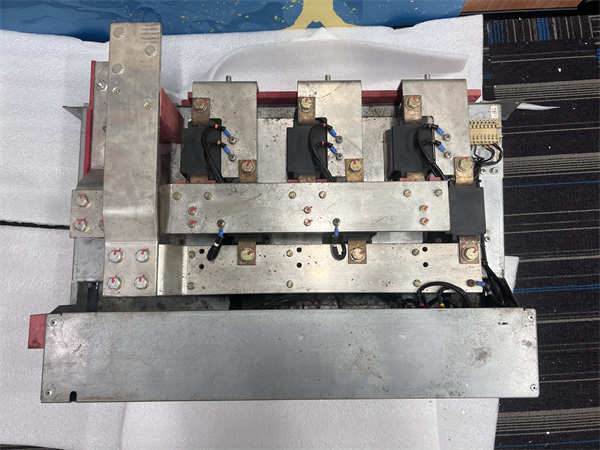

The GE MVR1600-4601 is a solid-state reduced voltage motor starter from GE (now part of ABB's Industrial Automation portfolio). This intelligent starter is designed to control the starting and stopping of three-phase AC induction motors, providing a smooth, controlled acceleration and deceleration to protect both the motor and the driven equipment.

In a municipal water treatment plant, a large 400HP raw water pump must be started daily. A direct-on-line start would cause a massive current inrush, stressing the electrical grid and creating a damaging water hammer effect in the pipeline. The GE MVR1600-4601 soft starter is installed in the motor control center (MCC). Upon start command, it gradually ramps up the voltage applied to the motor, allowing the pump to accelerate smoothly to full speed. This controlled start, managed by the MVR1600-4601, eliminates water hammer, reduces mechanical stress on the pump and piping, and significantly lowers the starting current, preventing disruptive voltage dips across the facility.

Main Parameters | Value/Description |

Product Model | GE MVR1600-4601 |

Manufacturer | General Electric (GE) |

Product Category | Solid-State Reduced Voltage Motor Starter (Soft Starter) |

Rated Voltage | 460V AC |

Current Rating | Designed for a specific current range (e.g., up to 1600A, depending on design) |

Control Method | Solid-state, using thyristors (SCRs) to control voltage ramp |

Starting Characteristics | Adjustable starting voltage, current, and ramp time |

Stopping Characteristics | Optional soft stop (deceleration ramp) |

Protection Features | Integrated overload protection, phase imbalance, and undercurrent detection |

Communication Protocol | Often supports Modbus RTU or other protocols for system integration |

Enclosure | Typically designed for mounting in a motor control center (MCC) bucket |

The GE MVR1600-4601 utilizes advanced power electronics to solve traditional motor-starting challenges, offering key innovations:

· •Innovation Point 1: Thyristor-Based Voltage Control: The core of the MVR1600-4601 is its use of six Silicon-Controlled Rectifiers (SCRs) - two per phase. By precisely controlling the firing angle of these SCRs, the starter can gradually increase the voltage supplied to the motor during startup. This provides a seamless, stepless acceleration curve, a significant improvement over the jerky starts of electro-mechanical starters.

· •Innovation Point 2: Integrated Motor Protection and Diagnostics: Beyond starting control, the MVR1600-4601 incorporates comprehensive motor protection features. It continuously monitors current, voltage, and temperature. It can detect faults like phase loss, imbalance, and locked rotor, providing advanced warning and shutting down the motor to prevent damage. This eliminates the need for separate overload relays, simplifying the control scheme.

· •Innovation Point 3: Pump Control and Anti-Hammer Features: Specifically for pump applications, the MVR1600-4601 often includes specialized stopping algorithms. The "soft stop" function gradually reduces torque, preventing the sudden valve closure and pressure surge that causes water hammer. This protects the pump, valves, and pipelines from catastrophic damage, extending the lifecycle of the entire system.

A mining operation was experiencing frequent failures of conveyor belt drive shafts and gearboxes due to the high-inertia starting torque of the large motors. Replacing the traditional star-delta starters with GE MVR1600-4601 soft starters resulted in a dramatic improvement. The adjustable torque ramp-up allowed the conveyor belt to begin moving smoothly, eliminating the shock loading that was damaging mechanical parts. The maintenance manager reported a 60% reduction in mechanical drive component failures in the first year, leading to significantly lower maintenance costs and increased production uptime, directly attributable to the controlled starting provided by the MVR1600-4601.

The GE MVR1600-4601 is a key component in a motor management system. Essential related products include:

· •GE DS200 Drive System Components: While a drive is for speed control, components like control boards or power modules may share complementary technology with the starter family.

· •GE F650 Relay: A sophisticated protection relay that can be used in conjunction with the MVR1600-4601 for even more granular system-level protection and monitoring.

· •GE MVB / MVBc Motor Control Buckets: The standardized MCC buckets designed to house starters like the MVR1600-4601.

· •GE EntelliGuard GU Circuit Breakers: The upstream circuit breaker providing short-circuit protection for the branch circuit containing the MVR1600-4601 and the motor.

· •GE HMI Comm Module: An communication option module that can be added to the MVR1600-4601 to enable integration with a DCS or SCADA system for remote monitoring and control.

Installation of the GE MVR1600-4601 should be performed by qualified electrical personnel. It is typically mounted within a designated MCC bucket. The process involves securing the unit, connecting the main power cables, and wiring the low-voltage control signals for start/stop commands and status feedback. Configuration is done via a keypad interface to set parameters like ramp time and current limit.Maintenance is minimal due to the solid-state design with no moving parts. Primary tasks involve periodic inspection of connections for tightness and ensuring the cooling fins are clean and unobstructed. The built-in diagnostics provide valuable data for predictive maintenance. We offer comprehensive support, from initial system design and startup assistance to troubleshooting and spare parts provisioning, ensuring the long-term reliability of your motor-driven systems.

扫一扫咨询微信客服

扫一扫咨询微信客服