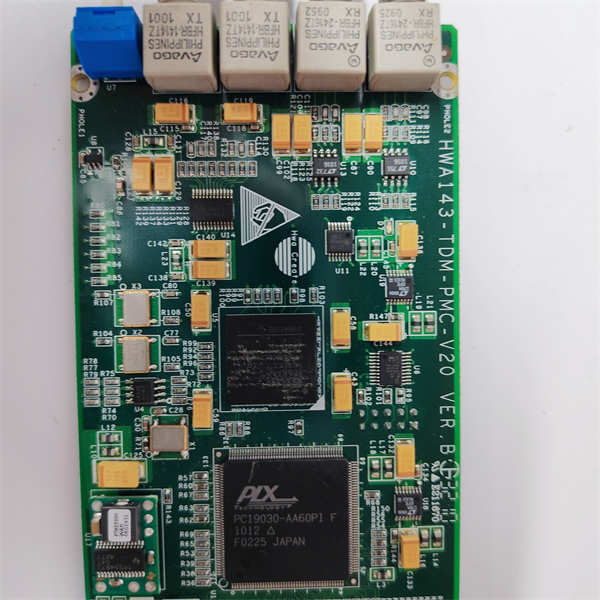

The GE HWA143-TDM-PMC-V20 is a critical Triple Modular Redundant (TMR) controller module designed for GE's Mark VIe turbine control system. This high-reliability safety controller provides triple-redundant protection for critical equipment in power generation and industrial applications, ensuring maximum system availability and operational safety.

In a combined cycle power plant, the gas turbine requires ultra-reliable overspeed protection to prevent catastrophic damage. The GE HWA143-TDM-PMC-V20 TMR controller continuously monitors turbine speed through three independent channels. Each channel processes the speed signal simultaneously, with the final output determined by a 2-out-of-3 voting logic. This architecture ensures that even if one channel fails, the protection system remains fully functional, allowing the turbine to operate safely while maintenance is scheduled. The HWA143-TDM-PMC-V20's robust design is essential for preventing equipment damage and ensuring grid stability.

| Main Parameters | Value/Description || | :--- || Product Model | GE HWA143-TDM-PMC-V20 || Manufacturer | General Electric (GE) || Product Category | Triple Modular Redundant (TMR) Safety Controller || Control System | GE Mark VIe Turbine Control System || Safety Level | Suitable for SIL 3 safety applications || Architecture | Triple Modular Redundant (TMR) with 2oo3 voting || Processor Type | High-performance safety processor || Communication | Support for industrial Ethernet protocols || Diagnostics | Comprehensive online diagnostics and testing || Environmental Rating | Designed for harsh industrial environments |

The GE HWA143-TDM-PMC-V20 implements advanced safety system technologies with several key innovations:

· •Innovation Point 1: True Triple Modular Redundant ArchitectureThe module employs three independent processing channels that operate in parallel. Each channel executes identical logic simultaneously, with final output determined by majority voting. This design ensures continuous operation even with a single channel failure, providing exceptional fault tolerance.

· •Innovation Point 2: Advanced Diagnostic CoverageIncorporates comprehensive built-in self-testing capabilities that continuously monitor module health. The diagnostics can detect over 99% of potential faults, providing early warning of issues and maintaining system integrity through automatic channel isolation when faults are detected.

· •Innovation Point 3: Seamless System IntegrationDesigned for perfect integration with the Mark VIe control system, supporting hot-swap replacement capabilities. This allows for maintenance without system shutdown, significantly improving plant availability and reducing maintenance costs.

A major refinery experienced recurring trips in their critical gas compressor unit, resulting in significant production losses. The existing safety system couldn't distinguish between genuine trips and spurious signals. Implementation of the GE HWA143-TDM-PMC-V20 TMR controller provided intelligent voting logic that eliminated nuisance trips while maintaining critical protection. The system achieved 100% operational availability in the first year, preventing an estimated $5M in production losses and enhancing overall process safety.

The GE HWA143-TDM-PMC-V20 works within a comprehensive safety system architecture:

· •GE IS200-series I/O Modules: Various input/output modules that interface with the HWA143-TDM-PMC-V20 for signal processing

· •GE T8311 Controller: Turbine control processor that works in conjunction with the safety system

· •GE HWA114 Base Plate: Mounting and connection base for the TMR controller modules

· •GE HWA143 Complementary Modules: Other modules in the HWA143 series that provide complete TMR solution

· •GE EX2100 Excitation System: Works with the turbine control system for complete power generation control

Proper installation requires GE-certified technicians following strict electrostatic discharge (ESD) procedures. The module must be precisely aligned with the baseplate guides and firmly seated to ensure proper connector engagement. Initial configuration requires specialized software tools and should only be performed by qualified personnel.Routine maintenance includes periodic diagnostic reviews and environmental condition monitoring. The module's hot-swap capability allows for replacement during operation, with automatic integration into the TMR system. We provide comprehensive lifecycle support including configuration services, firmware updates, and 24/7 technical support to ensure optimal system performance and safety integrity.

扫一扫咨询微信客服

扫一扫咨询微信客服