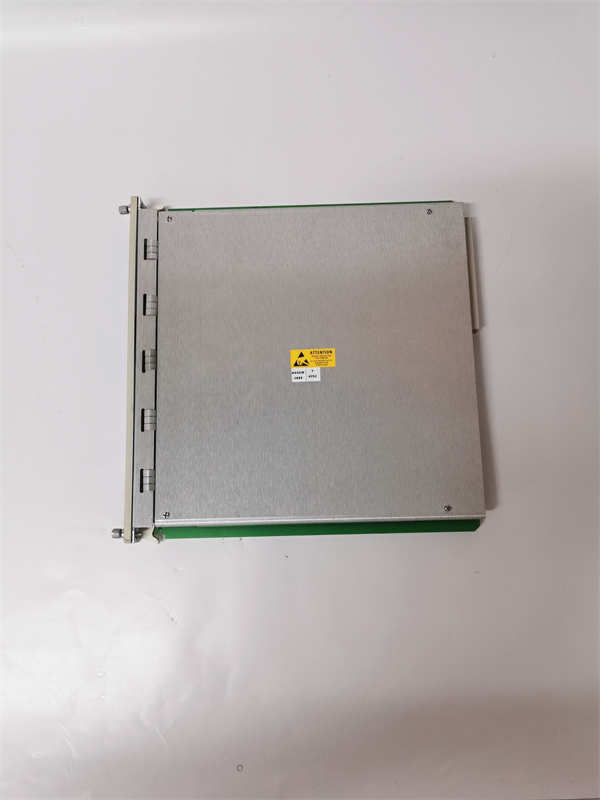

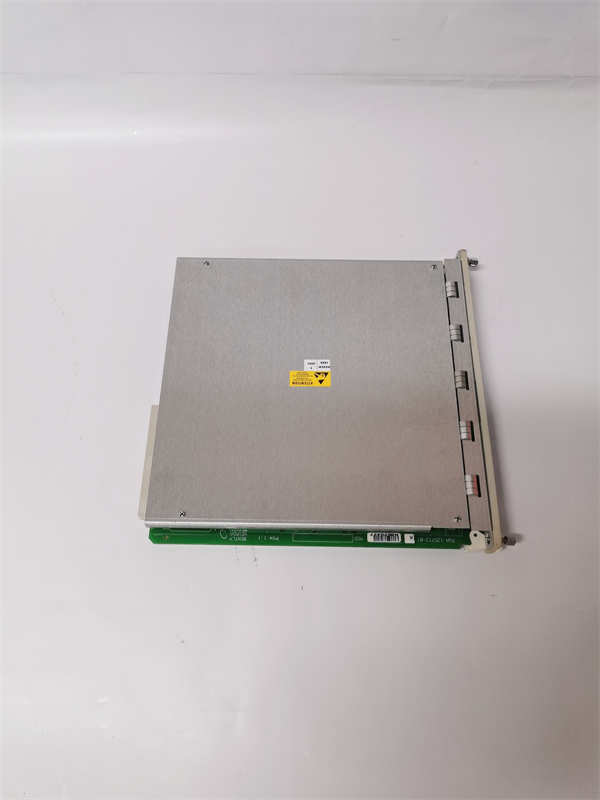

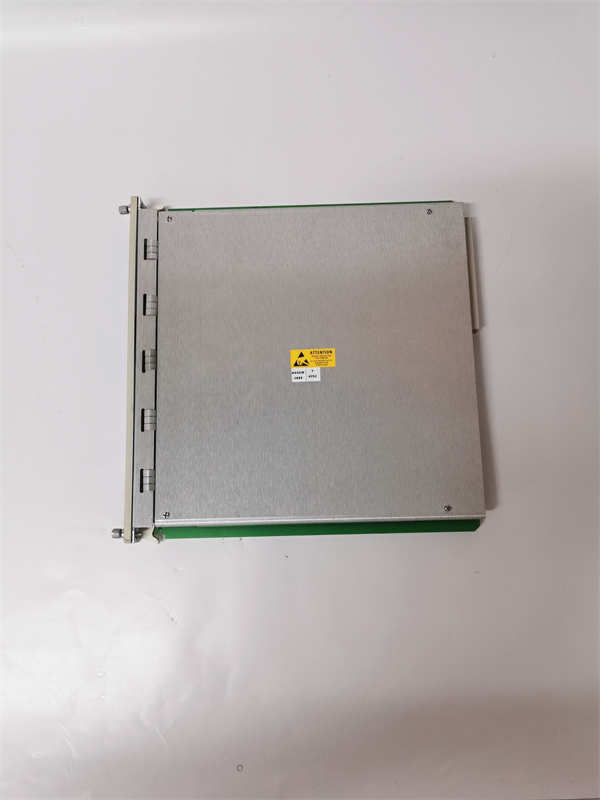

The BENTLY NEVADA 3500/32 125712-01 is a dual-channel axial position monitor module designed for the Bently Nevada 3500 machinery protection system. This critical safety module continuously monitors the axial thrust position of turbine and compressor shafts to prevent catastrophic damage to thrust bearings.

In a steam turbine power generation unit, the rotor assembly is subject to significant axial forces during startup, shutdown, and load changes. The BENTLY NEVADA 3500/32 125712-01 module monitors proximity probes installed at the thrust collar. If axial displacement approaches dangerous levels that could indicate thrust bearing failure, the module triggers alarms and initiates a turbine trip within milliseconds, preventing catastrophic metal-to-metal contact and potential rotor destruction. This application solves the critical pain point of thrust bearing protection, which is essential for avoiding extended downtime and costly repairs.

Main Parameters | Value/Description |

Product Model | BENTLY NEVADA 3500/32 125712-01 |

Manufacturer | Bently Nevada (Baker Hughes) |

Product Category | Dual-Channel Axial Position Monitor |

Compatible System | Bently Nevada 3500 Series Rack |

Number of Channels | 2 Independent Redundant Channels |

Measurement Range | Typically -20 to +20 mils (-500 to +500 μm) |

Input Signals | Accepts signals from eddy-current proximity probes |

Output Signals | 4-20mA proportional output per channel |

Alarm Relays | Independent Alert and Danger relays per channel |

Power Supply | Powered by the 3500 rack backplane |

Keyphasor® Reference | Required for phase reference and timing |

· •Innovation Point 1: Dual-Channel Redundant Safety Architecture. The 3500/32 125712-01 employs two completely independent monitoring channels with separate power supplies, processors, and relay outputs. This redundancy ensures continuous protection even if one channel fails, meeting critical safety requirements and preventing single points of failure in the protection system.

· •Innovation Point 2: Advanced Thrust Position Algorithm. The module uses sophisticated algorithms to accurately calculate the true axial position from the proximity probe signals, accounting for factors like thermal expansion and electrical runout. This ensures precise measurement reliability under all operating conditions, from cold startup to full-load operation.

· •Innovation Point 3: Comprehensive Diagnostic Capabilities. The module continuously performs self-diagnostics on its internal circuitry and monitors the health of connected proximity probes and cabling. It can detect faults such as probe failure, cable breaks, or short circuits, providing early warning of system degradation before protection is compromised.

A natural gas compressor station experienced repeated thrust bearing failures on their centrifugal compressors, resulting in over $500,000 in repair costs and production losses per incident. After installing the BENTLY NEVADA 3500/32 125712-01 modules, operators gained real-time visibility into axial position trends during transient operations. The system detected developing thrust problems during startup sequences, allowing operators to adjust procedures before damage occurred. This proactive approach eliminated thrust bearing failures for three consecutive years, achieving full ROI within 18 months through avoided downtime and repair costs.

· •BENTLY NEVADA 3500/15 Proximitor® Power Supply: Provides necessary power to the proximity probes connected to the 3500/32 module.

· •BENTLY NEVADA 3300 XL 8mm Proximity Probes: The industry-standard sensors that measure axial position for the 3500/32 module.

· •BENTLY NEVADA 3500/20 Vibration Monitor: Complementary module for radial vibration monitoring, often used alongside the 3500/32 for comprehensive machinery protection.

· •BENTLY NEVADA 3500/92 Communication Gateway: Enables integration of 3500/32 data into plant DCS and asset management systems.

· •BENTLY NEVADA System 1® Software: Advanced diagnostics platform that analyzes trends and data from the 3500/32 module for predictive maintenance.

Installation of the BENTLY NEVADA 3500/32 125712-01 requires insertion into an available slot of the 3500 series rack. Proper configuration of alarm setpoints and probe parameters is essential through dedicated software. Critical alignment of proximity probes and calibration of the entire measurement loop ensures accurate and reliable operation.Routine maintenance includes periodic verification of probe gap voltages and calibration checks. The module's LED indicators provide immediate status information, while software diagnostics enable proactive maintenance planning. The robust design ensures long-term reliability in harsh industrial environments. We provide comprehensive lifecycle support including system design, configuration assistance, and 24/7 technical support with guaranteed availability of genuine BENTLY NEVADA 3500/32 125712-01 modules.

扫一扫咨询微信客服

扫一扫咨询微信客服